Product Introduction

SGWEIGH Dynamic Checkweigher Conveyor Scale is typically used in various industries to ensure product weight accuracy and quality control by automatically rejecting items that are underweight, overweight, or otherwise non-compliant.

Tech Specifications

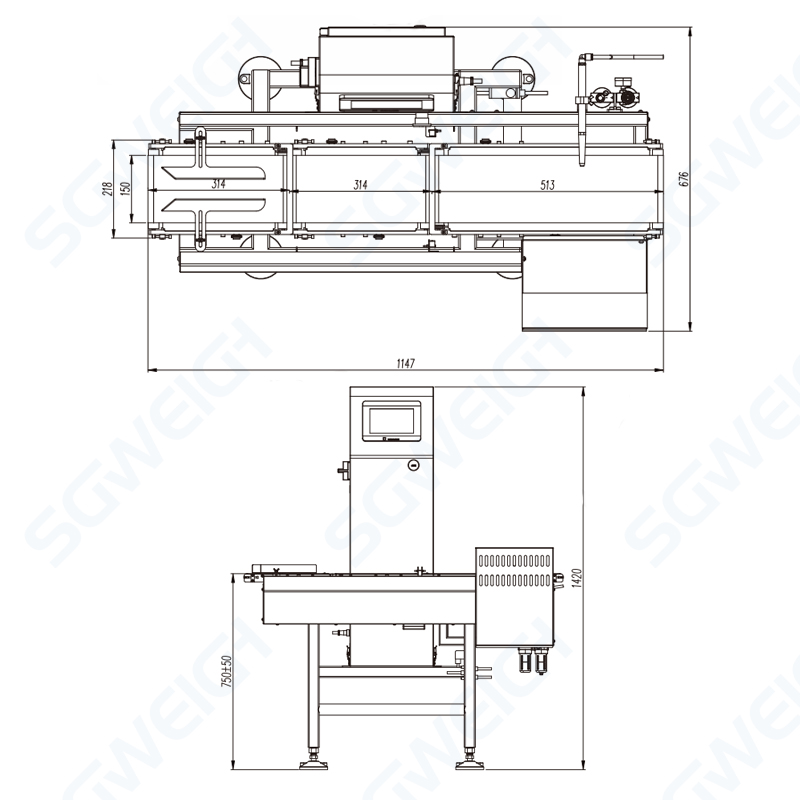

Type:SG-150U

Weighing Range:3-500g

Limited of product:L: 200 W:150 H: 3-200mm

Accuracy:±0.1g Depends on product

Division Scale:0.1g

Belt Speed:0- 60m/min

Max Speed:150 pcs/min

Belt Width:150mm

Machine Weight:60kg

Power Supply:AC 110/220V±10% 50HZ

Power:100W

Main Material:SUS304 stainless steel

The above detection accuracy is for reference only. The actual detection accuracy will be obtained after testing.

Special specifications can be customized according to customer requirements.

Main Features

High-Speed Weighing: Supports continuous, real-time weight measurements without slowing down the production line.

Rejector Mechanism: Comes equipped with pneumatic pushers, diverters, or flap gates to remove non-compliant items.

Touch Screen Interface: Allows easy parameter setting, calibration, and display of weighing data.

Customizable Settings: Can be set up for different weight ranges and product dimensions.

Data Logging: Captures and stores weight records for traceability and quality assurance.

Integration Options: Can be integrated with existing conveyor systems and other automation equipment.

Application

Food and Beverage Industry: Checking individual product weights (e.g., snacks, dairy products).

Pharmaceuticals: Ensuring correct dosage and package weights.

Manufacturing: Weight checking for components and parts.

Our Company

Our Customers

Our Exhibitions

FAQ

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2. What are your company’s requirements for payment terms?

A: TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.,

Q3: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

Kindly Remind

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference.Thank you.

●What product?

●Product weight?

●Product size?

●Speed requirement?

●Accuracy requirement?