Product Summarize

Non-Standard Customized Inclined Conveyor Belt Metal Detector Machine refers to a metal detection system that is designed to inspect products or materials on an inclined conveyor belt. These systems are commonly used in industries such as food processing, pharmaceuticals, and mining to ensure that the final product is free of metal contaminants.Welcome to consult for quotation information!

Product Parameter

SG-M400

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED falt key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

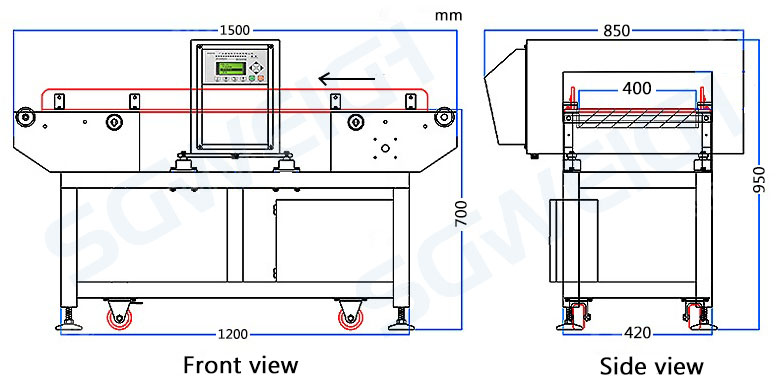

Dimensions: about L1500×W850×H950mm

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

Product Characteristics

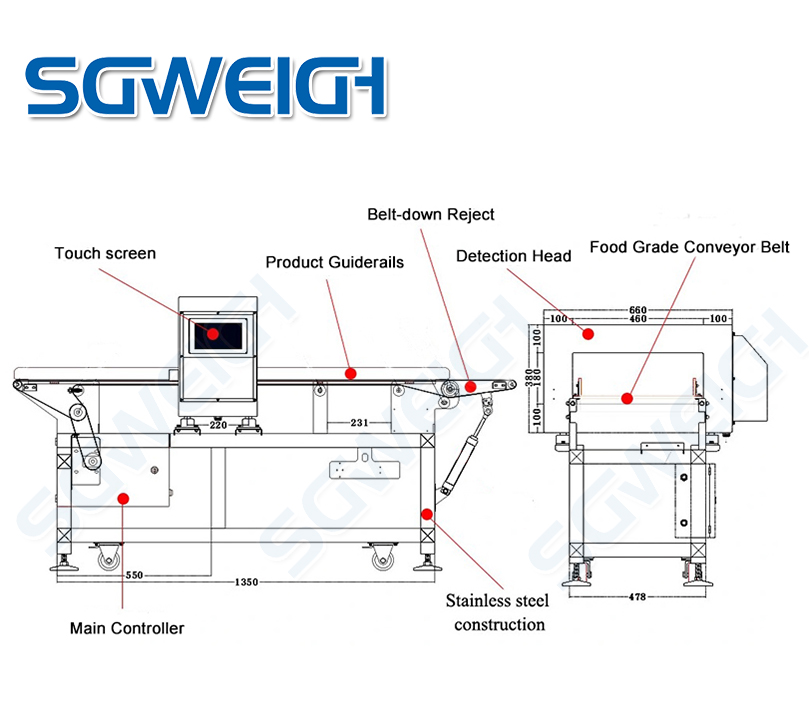

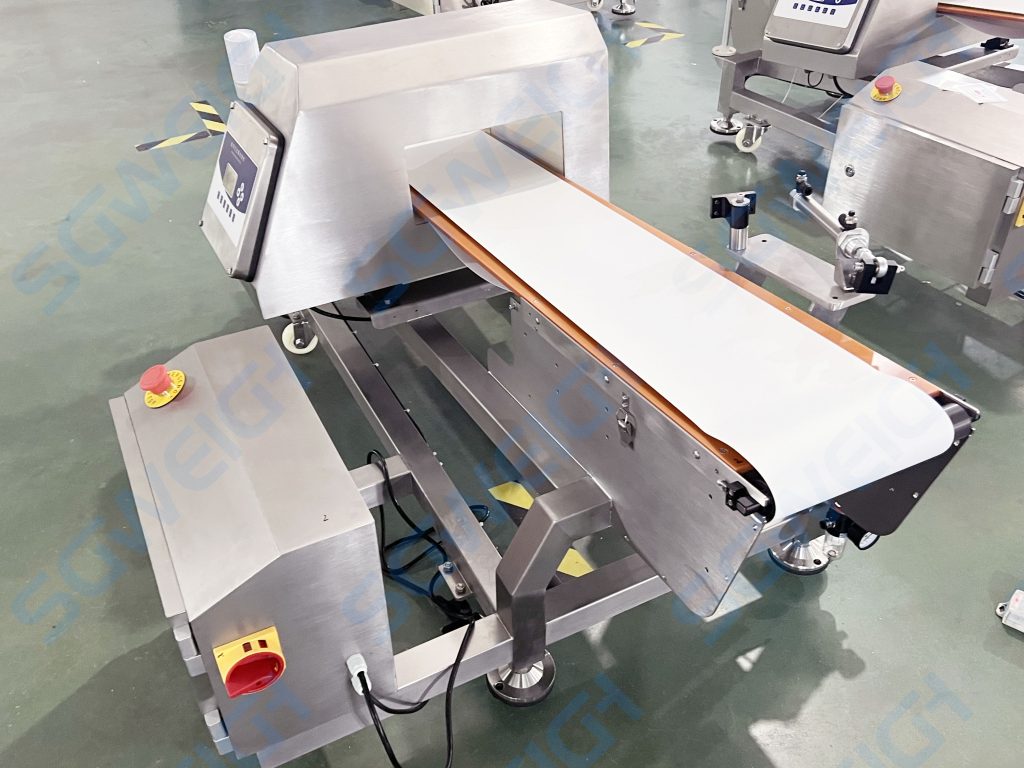

Conveyor Belt:

Incline metal detector machines are equipped with a conveyor belt that transports the product or material through the inspection area. The conveyor is inclined to allow for a smooth flow of items.

Metal Detector Head:

The metal detector head is the core component that detects metal contaminants. It typically consists of a coil or coils through which an electromagnetic field is generated. When metal objects pass through this field, disturbances are created, triggering an alarm or rejection mechanism.

Reject Mechanism:

Incline metal detector machines are often integrated with a reject mechanism to divert or remove contaminated products from the production line. Common rejection methods include air blasts, pushers.

Integration with Production Line:

Incline metal detectors are integrated into the production line to facilitate seamless inspection without disrupting the overall manufacturing process.

Specific Application

Company Profile

Customer Visit

Exhibition

Packaging&Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Hot Labels

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Checkweigher and Metal Detector Combo

Convenient Checkweigher