Product Introduction

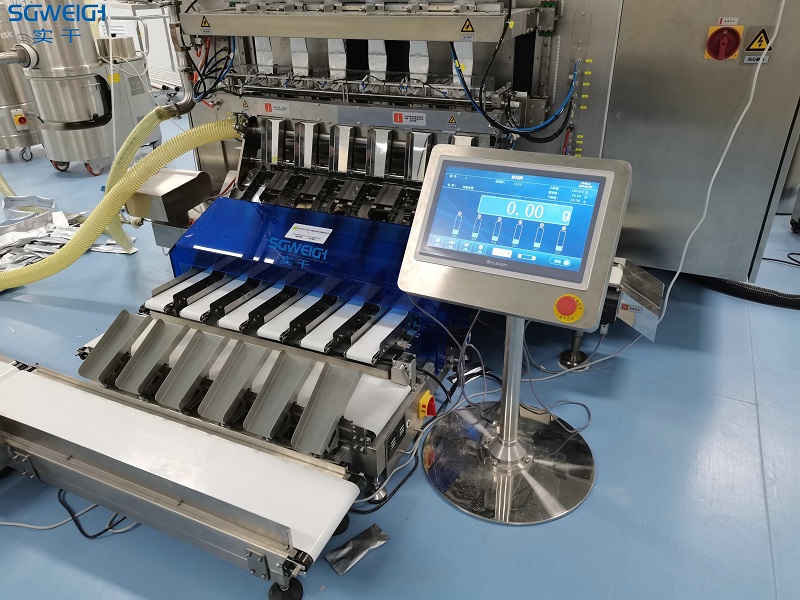

Multi-Lane Conveyor Weighing Machine is an advanced industrial machine used to check the weight of multiple columns of product simultaneously on a production line.2-6 Row High Speed Check Weigher is particularly useful in high-speed production environments where efficiency and accuracy are critical.

Tech Specifications

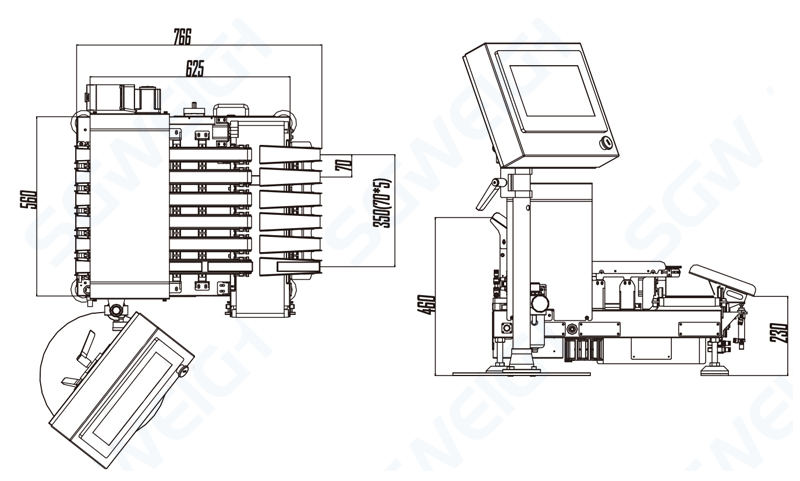

Model:SG-6X Mulit Lane Check Weigher

Weighing Range:1-50g

Minimum Scale:0.01g

Sorting Speed:70pcs/min (one lane)

Conveying Speed:20-100m/min

Operation Method:Touch operation

Conveying Direction:Can be placed according to the actual situation on site

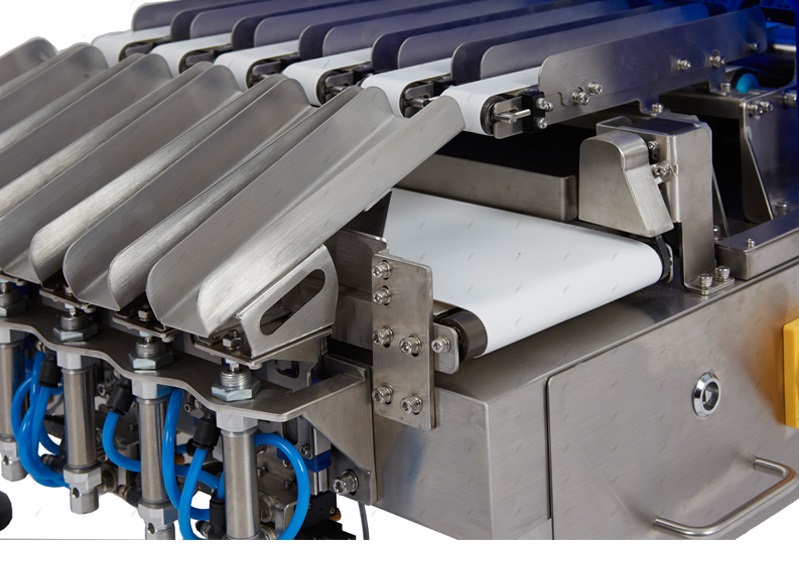

Elimination Method:Lifting Rejection

Belt Height From The Ground:450±50mm (can be customized according to customer requirements)

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

Power:About400W

Windshield:Thick acrylic (to avoid airflow interference)

Main Features

1. Data from multiple channels can be counted independently or comprehensively;

2. Checkweighing parameters can be set independently or uniformly;

3. One control module and display screen;

4. It has the accuracy and speed of multiple single-row checkweighers;

5. It can be monitored remotely in real time;

6. It saves space and is low in cost.

Application

Application

Our Company

Our Customers

Our Exhibitions

Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

FAQ

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2. What are your company’s requirements for payment terms?

A: TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.,

Q3: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

Kindly Remind

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference.Thank you.

●What product?

●Product weight?

●Product size?

●Speed requirement?

●Accuracy requirement?