Product Introduction

Intelligent High Efficient Dual Metal Detector Machine typically refers to a metal detection system that incorporates two separate metal detectors into a single unit. These systems are often used in various industries for enhanced metal detection capabilities.

Technical Parameters

Detection method: Double balanced coil induction method

Detection sensitivity: iron (φmm) 0.6-0.8, stainless steel (φmm): 1.5-2 non-ferrous (φmm): 1.2-2.3

Induction adjustment: microcomputer control

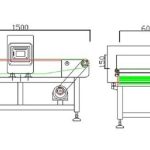

Detection width: 600mm (can be customized)

Detection height: 120mm (can be customized)

Alarm method: Sound and light alarm after detecting metal foreign matter, the conveyor belt automatically stops or optional automatic rejection device

Power supply: AC220V 50-60Hz

Power: about 140W

Overall dimensions: L1650-H1050*W900(mm)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

Main Features

Increased Sensitivity:

Combining two metal detectors can improve sensitivity and accuracy. The dual configuration allows for more comprehensive coverage and the ability to detect smaller or more challenging metal contaminants.

Multi-Frequency Detection:

Some dual metal detectors operate at multiple frequencies simultaneously. This can be advantageous in environments where different types of metals or alloys need to be detected.

Redundancy:

Having two metal detectors in a dual system can provide redundancy. If one detector fails or requires maintenance, the other can continue to operate, minimizing downtime in production processes.

Enhanced Discrimination:

Dual metal detectors may be designed to discriminate between different types of metals. This is especially useful in applications where certain metals are acceptable while others are considered contaminants.

Versatility:

The dual setup can be configured to handle various types of materials and applications. For example, in the food industry, it might be used for both bulk and packaged goods.

Application

Our Company

Our Customers

Our Exhibitions

Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

After Sale Service

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Shigan Industrial Co,.Ltd solemnly promises you with the principles of preferential prices, considerate service and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally check the whole process and performance of the product, and then pack and ship the product after it is confirmed to be qualified.

2. Product price commitment:

Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

Product delivery time: Try to meet user requirements. If there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Hot Labels