Selecting a Checkweigher for fragile products requires careful consideration to ensure that the machine can handle the products gently while still providing accurate weight measurements. Here are some key factors to consider when selecting a checkweigher for fragile products:

1.Gentle Handling: Look for a checkweigher that is designed to handle fragile products gently. This may include features such as soft belts, vibration dampening, and controlled acceleration and deceleration of the conveyor belt.

2.Adjustable Speed: Choose a checkweigher with adjustable speed settings so that you can slow down the conveyor belt when handling fragile products. This can help reduce the risk of damage during weighing.

3.Accuracy: Select a checkweigher that offers high accuracy to ensure that weight measurements are precise. This is important for meeting quality control standards and minimizing product giveaway.

4.Customizable Settings: Look for a checkweigher that allows you to customize settings such as weight tolerances and rejection thresholds to suit the specific requirements of your fragile products.

5.Integration with Existing Equipment: Ensure that the checkweigher can be easily integrated into your existing production line and works seamlessly with other equipment, such as filling machines or packaging machines.

6.Reject Mechanism: Consider the type of reject mechanism offered by the checkweigher. For fragile products, a gentle reject mechanism such as an air blast or retracting belt may be preferable to prevent damage.

By considering these factors and selecting a checkweigher specifically designed for fragile products, you can ensure that your products are handled gently while still achieving accurate weight measurements.

Hot Labels

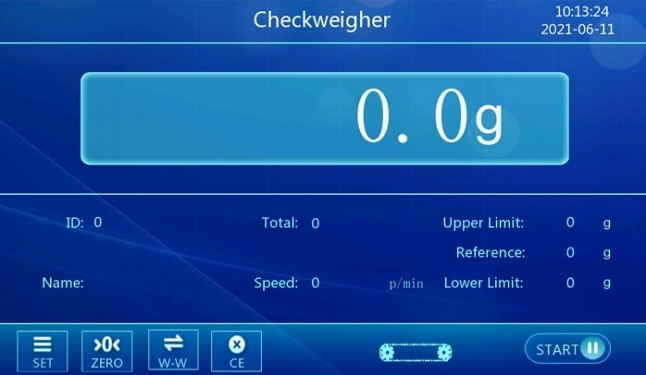

Online Checkweigher

Food Checkwiegher

Large Range Checkweigher

Weight Sorting Machine

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Weight Labeling Machine