High Quality Food Metal Detectors are indispensable tools in the food industry, safeguarding consumers from the potential hazards of metal contamination. These devices employ advanced technology to identify and reject products containing metal fragments, ensuring product safety and maintaining brand integrity.

How Do They Work?

Food metal detectors operate on the principle of electromagnetic induction. Metal contaminants passing through the detector’s field disrupt the electromagnetic balance, triggering an alarm.

Key Features of a High-Quality Food Metal Detector

Sensitivity: The ability to detect even the smallest metal particles.

Product compatibility: Suitable for various food products, including dry, wet, and frozen items.

Ease of use: User-friendly interface and minimal maintenance requirements.

Compliance: Adherence to industry standards and regulations.

Durability: Built to withstand harsh food processing environments.

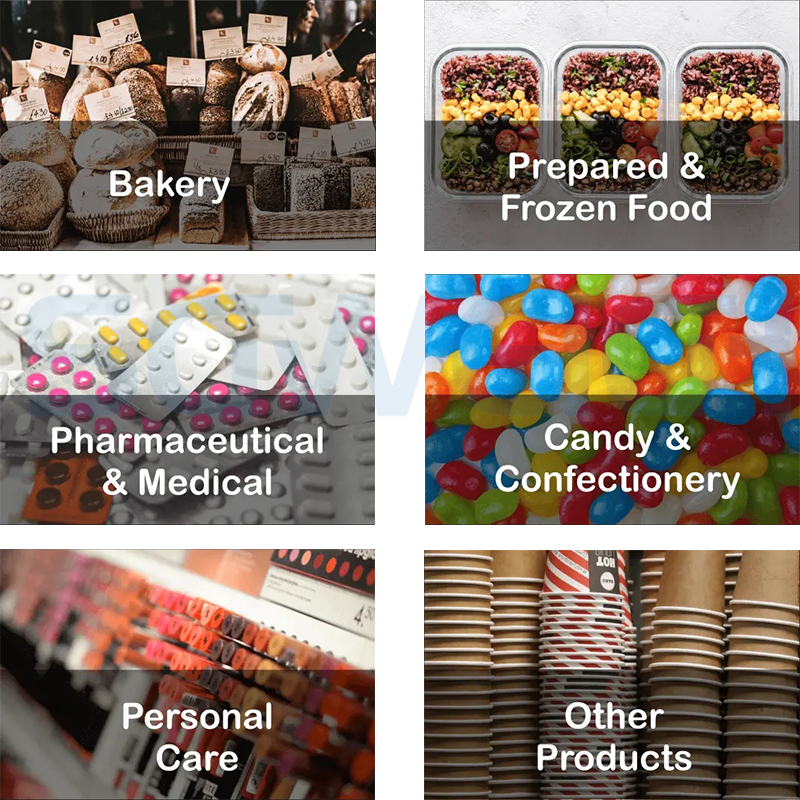

Applications in the Food Industry

Meat and Poultry: Detecting metal fragments in raw and processed meat products.

Dairy: Identifying metal contaminants in milk, cheese, and other dairy products.

Bakery: Preventing metal particles from entering bread, pastries, and baked goods.

Frozen Foods: Detecting metal in frozen vegetables, fruits, and prepared meals.

Confectionery: Ensuring the absence of metal in chocolates, candies, and other sweets.

Would you like to learn more about specific applications?Please contact us !