A Food Metal Detector Machine is an essential piece of equipment in the food industry designed to enhance food safety by identifying and eliminating metal contaminants in food products. Here are several ways in which these machines contribute to ensuring the safety of food:

Contaminant Detection:

Metal detectors are highly sensitive devices that can detect the presence of metal contaminants, such as ferrous, non-ferrous, and stainless steel particles, in food products. These contaminants can enter the food supply chain during various stages of processing, packaging, or transportation.

Compliance with Regulations:

Many food safety regulations and standards, such as those set by government agencies and international bodies, mandate the use of metal detectors in food processing facilities. Compliance with these regulations is crucial for maintaining the integrity of the food supply and ensuring public health.

Consumer Safety:

Detecting and removing metal contaminants from food products helps prevent consumers from ingesting harmful materials that could cause injury or health issues. This is especially important for products that are intended for direct consumption.

Brand Protection:

Contaminated food products can lead to product recalls, damage to brand reputation, and legal consequences. By incorporating metal detectors into the production process, food manufacturers can protect their brand and maintain consumer trust.

Quality Control:

Metal detectors contribute to quality control by ensuring that food products meet established safety standards. Consistently high-quality products enhance the reputation of the brand and contribute to customer loyalty.

Production Efficiency:

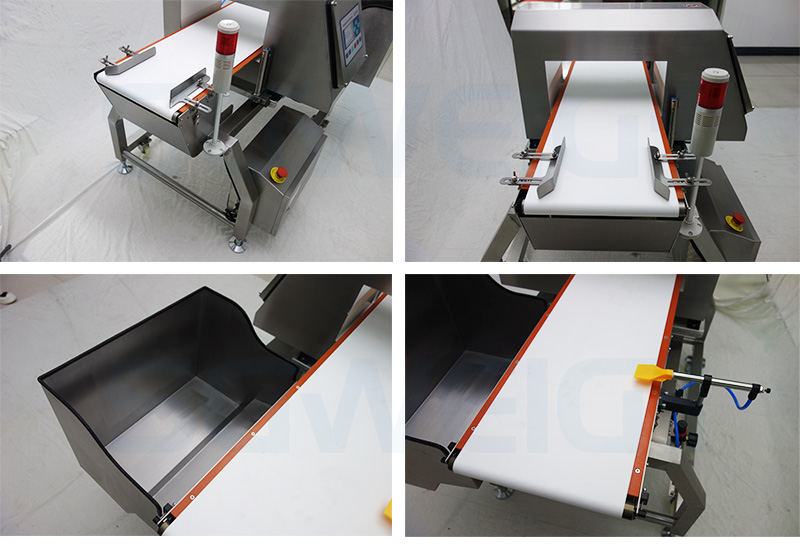

Metal detectors can be integrated into production lines, providing real-time monitoring without significantly slowing down the production process. This allows for efficient screening of large quantities of food products.

Versatility:

Food metal detectors are versatile and can be customized to suit different types of food products and packaging materials. They are adaptable to various production environments, including those with high-speed production lines.

Reduced Product Waste:

By identifying and rejecting only those products containing metal contaminants, the metal detector helps reduce unnecessary product waste. This targeted approach ensures that safe and uncontaminated products continue through the production process.

In summary, food metal detector machines play a crucial role in enhancing food safety, ensuring compliance with regulations, protecting brands, and maintaining the quality of food products. Incorporating these devices into food processing operations is a proactive measure to prevent metal contamination and contribute to the overall safety and integrity of the food supply chain.

Hot Labels

Online Checkweigher

Food Checkwiegher

Large Range Checkweigher

Weight Sorting Machine

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Weight Labeling Machine

Food Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Pipeline Metal Detector

Metal Detector Combination Checkweigher