Product Overview

Conveyor Metal Detector Combined With Check Weigher for Food Industry, which greatly improves the safety and reliability of production. It is used for post-packaging weight and metal detection in the fields of food, medicine, chemical industry, textile, toy, etc.

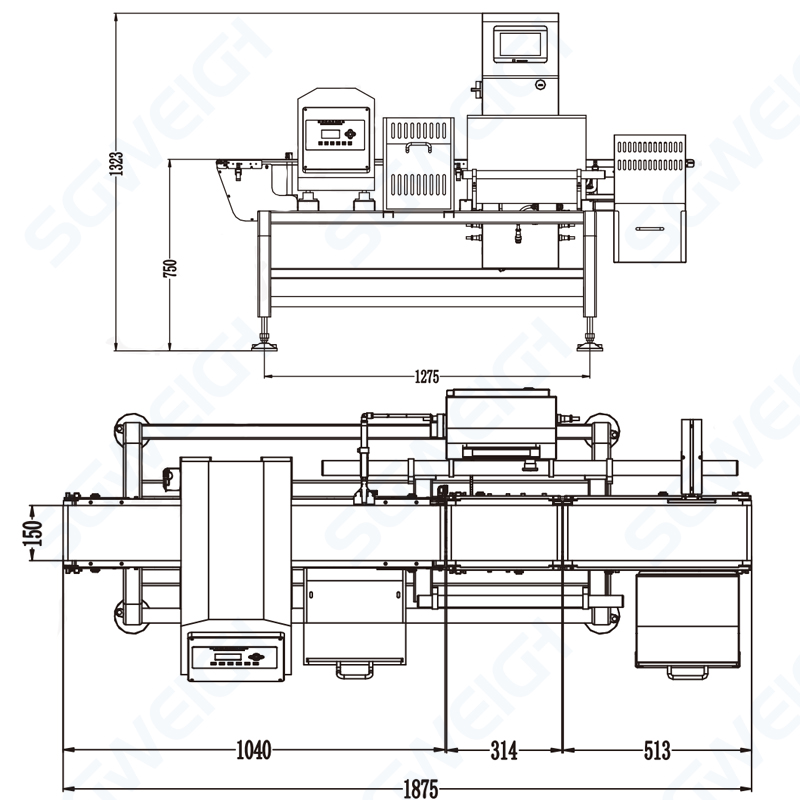

Product Parameter

Model: SG-JS150

Detection hole width: 150mm

Detection hole height: 100-200mm

Detection sensitivity:

H-100mm: Fe≥Φ0.8mm,SUS≥Φ1.2mm

H-120mm: Fe≥Φ0.8mm,SUS≥Φ1.8mm

H-150mm: Fe≥Φ1.2mm,SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.5mm,SUS≥Φ2.5mm

Effective detection hole width: 150mm

Effective detection hole height: 100-200mm

Weighing range: 5-500g

Weighing accuracy: ±0.1g(Depends on products)

Conveyor belt height: 750mm (±50mm)

Conveying capacity: 10Kg/time

Delivery direction: from left to right

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED LCD flat button input

Machine weight: 240kg

Power requirements: AC220V 50HZ

Power: 300W

Dimensions: about L2267×W589×H1500mm (final design shall prevail)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

Standard Features

1. All in one stainless steel frame.

2. Equipped with precise load cell and high speed DSP technology.

3. Dynamic weighing compensation and zero tracking.

4. Fast preset shift, Automatic product study.

5. Rejector type optional.

6.IP65 Optional.

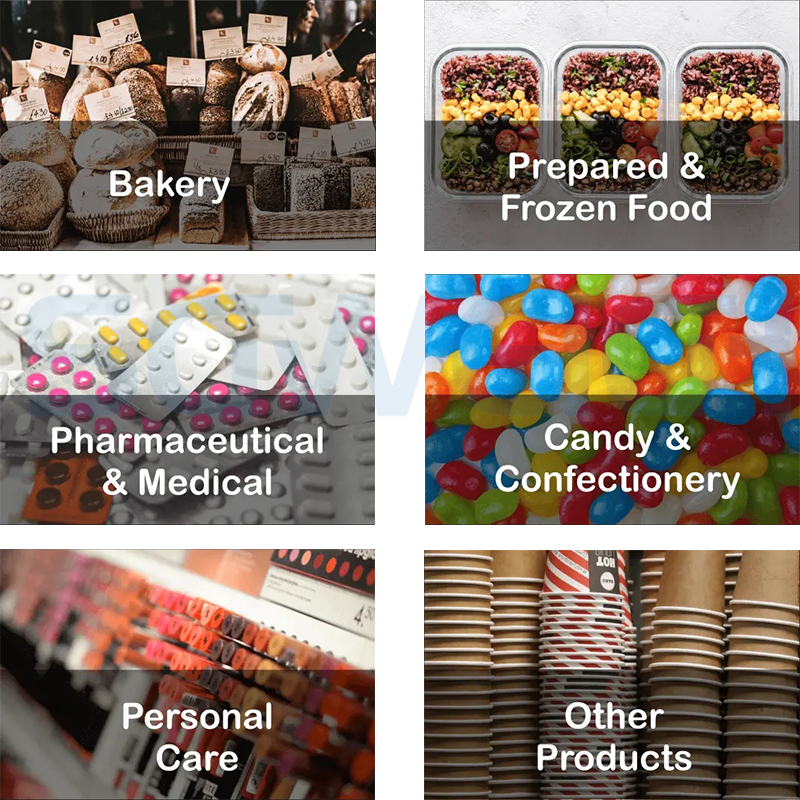

Scope of Application

Company Profile

Packaging&Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.