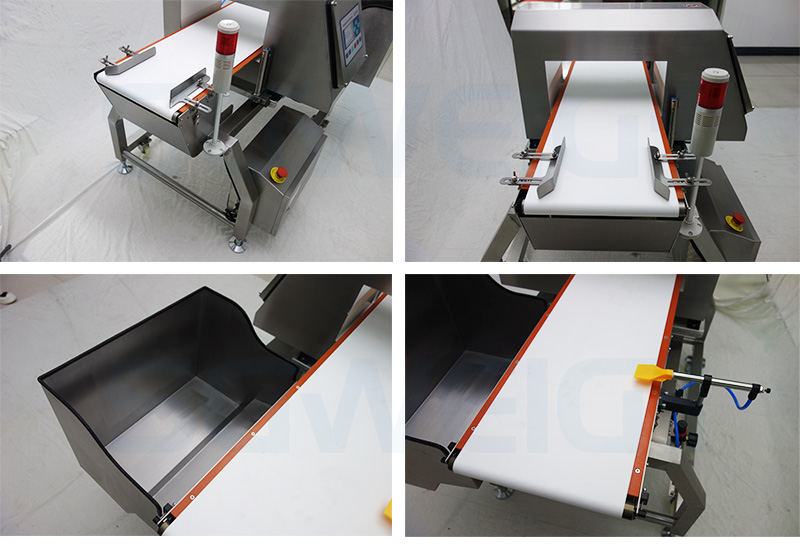

Metal Detector System for Inline Packaged and Unpackaged Products

Metal Detector System are used to inspect products for any metal contaminants that may be present.They are essential for ensuring product safety and quality in a variety of industries, including food, pharmaceutical, and plastics.

Metal Detector Machine is able to sense the presence of any metal in the product, and will trigger an alarm or reject mechanism if any metal is detected.

Conveyor and tunnel metal detection systems can be used to detect a variety of metals, including ferrous metals (such as iron and steel), non-ferrous metals (such as aluminum and copper), and stainless steel. The sensitivity of the metal detector can be adjusted to meet the specific needs of the application.

Here are some of the benefits of using Metal Detector Machine:

Improved product safety: By detecting and removing metal contaminants from products.

Enhanced product quality: Metal contaminants can damage processing equipment and reduce the quality of finished products. Metal Detector Machine can help to ensure that only high-quality products are produced.

Reduced waste: By removing metal contaminants from products before they are packaged,Metal Detector Machine can help to reduce waste.

Increased efficiency:Metal Detector Machine can help to improve production efficiency by reducing the need for manual inspection of products.