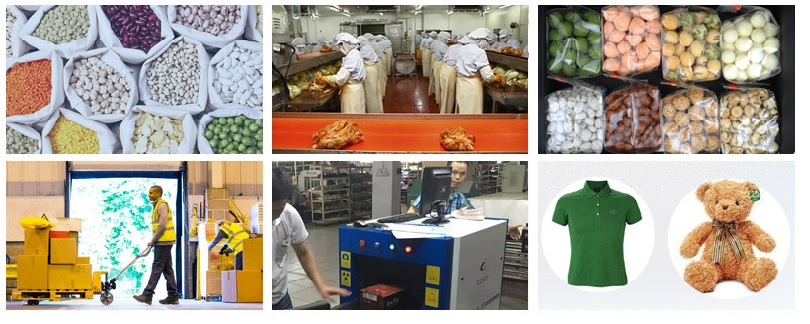

Metal Detectors are usually designed and manufactured to accommodate products of various shapes and sizes to meet the needs of different industries and applications. These include but are not limited to the following:

Solid products: Metal detectors can easily detect various solid products, such as food, medicine, packaging materials, wood, metal products, etc. They can detect metal foreign objects or metal fragments in the products.

Liquid products: Some metal detectors are specially designed for liquid products, such as beverages, chemicals, liquid pharmaceuticals, etc. They can detect metal foreign objects or particles in liquids.

Powder and granular products: Metal detectors can be applied to various powder and granular products, such as flour, spices, cosmetic powders, granular medicines, etc.

Bulk products: Metal detectors can also be used for bulk products such as barley, coal, sand and gravel, etc. They can detect metallic foreign objects in bulk materials.

Packaging products: Metal detectors are usually able to detect packaging products, such as metal cans, aluminum foil bags, food packaging, etc., to ensure that there are no metal foreign objects in the packaging materials.

Rolled products: Some metal detectors are specially designed for rolled products, such as paper rolls, metal wires, cables, etc. They can detect metal foreign objects in rolled products.

In order to adapt to different forms of products, metal detectors usually have adjustable parameters and multiple detection modes to ensure their flexibility and adaptability. Operators can adjust the settings as needed to adapt to the detection requirements of different products, which helps To ensure product quality and safety.