Product Introduction

The Automatic High Speed Check Weigher can detect overweight and underweight substandard products in the production line in real time and online.Check Weigher For Packed & Unpacked Food can also count and display production data, and export the weight data of each product to the computer, which can be used for product quality analysis and production management.Welcome to consult for quotation information!

Technical Parameters

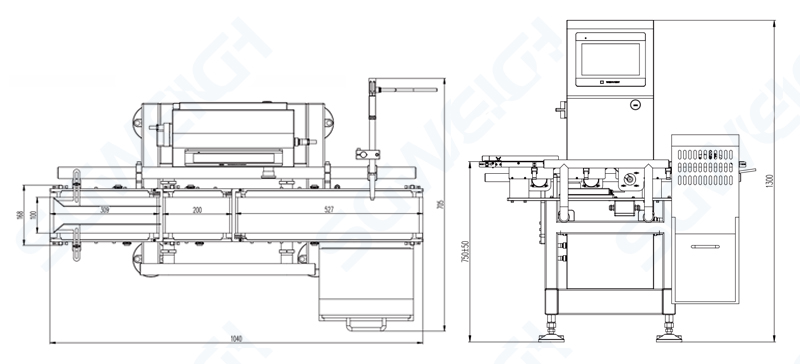

Type:SG-100

Weighing Range:2-300g

Limited of product:L:100 W:100 H:2-150mm

Accuracy:±0.05g Depend on products

Division Scale:0.01g

Belt Speed:0-90m/min

Max Speed:260 pcs/min

Belt Width:100mm

Machine Weight:70kg

Power Supply:AC 110/220V ±10% 50HZ

Power:100W

Main Material:SU304 stainless steel

Main Features

1.Strong practicality: 10-inch high-color, high-resolution human-machine interface, easy and friendly operation.

2.High stability: 24-hour high-speed, high-precision operation. Advanced and rigorous design concepts greatly reduce mechanical system failures and improve production efficiency.

3.High speed and high precision: Using high-speed and high-precision German HBM sensors.

4.Materials and accessories: The entire body structure is made of 304 stainless steel, which is anti-theft, anti-corrosion and has a long service life.

5.Easy maintenance: unique conveyor belt structure design, modular design, easy disassembly, assembly and cleaning, protection grade IP65.

6.Easy to switch: 100 product formulas can be stored, and product parameters can be switched easily.

Application

Our Company

Our Customers

Our Exhibitions

Package & Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

After Sale Service

★Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

★In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

★Installation

◎We provide videos and instruction manual to show the process of installation.

◎We provide training for installation for free in our factory.

◎We can send technician to buyer’s factory to install the machine and provide training service.

★After-sales

◎ For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

◎We will have one year free warranty period. During warranty period, if there is any malfunction for the machine, we will try our best to solve the problem within 24 hours. If there are some spare parts needed to be replaced, we will provide the spare parts for free. Beyond warranty, we will charge the cost price for spare parts.

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo