The main differences between Large Capsule Checkweighers and Mini Capsule Checkweighers are size, detection capability, applicable scenarios and degree of automation. The specific comparison is as follows:

| Size and Structure | ||

| Comparison item | Large Capsule Checkweigher | Mini Capsule Checkweigher |

| Size | Large, usually integrated into the assembly line | Small, suitable for laboratories or small batch production |

| Weight | Heavier (over 350kg) | Lighter (usually <50kg) |

| Structure | Multi-module combination (conveyor belt, sorting mechanism, etc.) | Integrated design, strong portability |

| Detection Capabilities | ||

| Comparison item | Large Capsule Checkweigher | Large Capsule Checkweigher |

| Detection speed | High speed (75000 PCS/HR) | High speed (6000 PCS/HR) |

| Accuracy | High (±0.1mg) | High (±0.1mg) |

| Applicable capsule specifications | Various sizes (00#~5# capsules can be adapted) | Usually for small capsules (1#~5# mainly) |

| Applicable Scenarios | ||

| Comparison item | Large Capsule Checkweigher | Large Capsule Checkweigher |

| Production scale | Large-scale continuous production (pharmaceutical factories, OEM factories) | Small-scale, R&D trial production, quality inspection laboratories Automation requirements |

| Automation requirements | Fully automatic sorting, data networking (GMP requirements) | Manual or semi-automatic, flexible operation |

| Environmental adaptability | Industrial-grade protection (dustproof, anti-static) | Suitable for use on clean benches or lab benches |

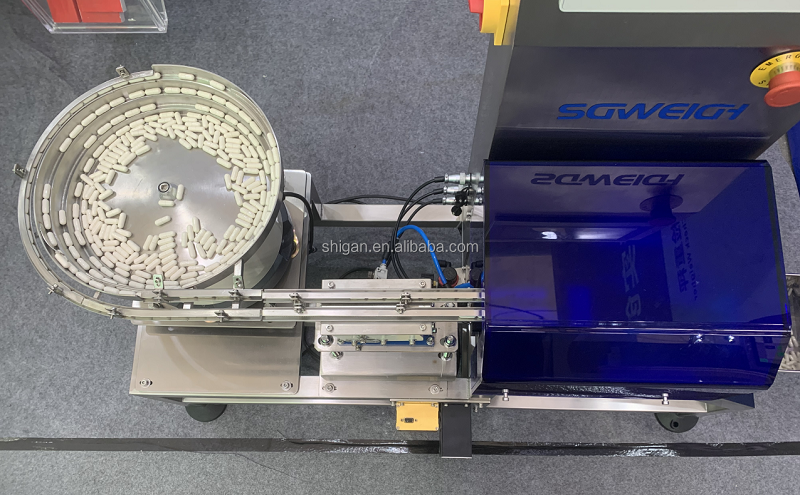

| Large Capsule Checkweigher | Mini Capsule Checkweigher |

|

|

|

|

How to choose?

Choose a large checkweigher:

✅ Large-scale production (such as pharmaceutical and health product production lines), full inspection

✅ High-precision, fully automatic sorting is required

✅ Meet GMP/FDA certification requirements

Choose a mini checkweigher:

✅ Laboratory research and development, small-scale trial production, sampling inspection

✅ Limited budget or space

✅ No need for complex sorting functions

If you need a capsule checkweigher, please tell me your application scenario (such as capsule type, production capacity requirements, etc.), and I can provide a more accurate solution!