Conveyor Industrial Metal Detector is a device used to detect metal foreign objects in products, widely used in industries such as food, pharmaceuticals, chemicals, and beverages to ensure product quality and safety.

1. Working principle

Electromagnetic induction: By emitting an electromagnetic field, metal foreign objects entering the detection area will interfere with the electromagnetic field. The device captures these changes through a receiver and issues an alarm.

Balanced coil system: typically using three coils (transmitting coil and two receiving coils), metal foreign objects entering can disrupt the balance between the coils and be detected.

2. Main components

Detection head: The core part, including the transmitting and receiving coils, is responsible for detecting metal foreign objects.

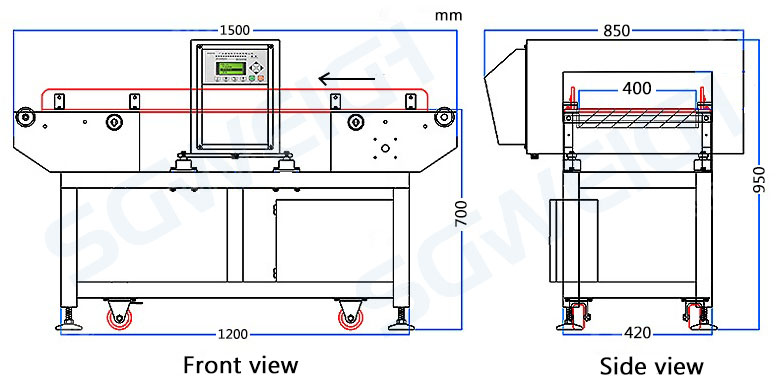

Conveyor system: A conveyor belt or pipeline used to transport products to be tested.

Control panel: used for setting parameters, displaying detection results, and operating equipment.

Removal device: When metal foreign objects are found, unqualified products are automatically or manually removed.

Power system: Provides power to equipment.

4. Advantages

High sensitivity: capable of detecting small metal foreign objects.

Automation: Implement automated detection and removal to improve efficiency.

Reliability: Stable operation, reducing false alarms and missed alarms.

Easy to operate: User interface friendly, easy to operate.