Product Overview

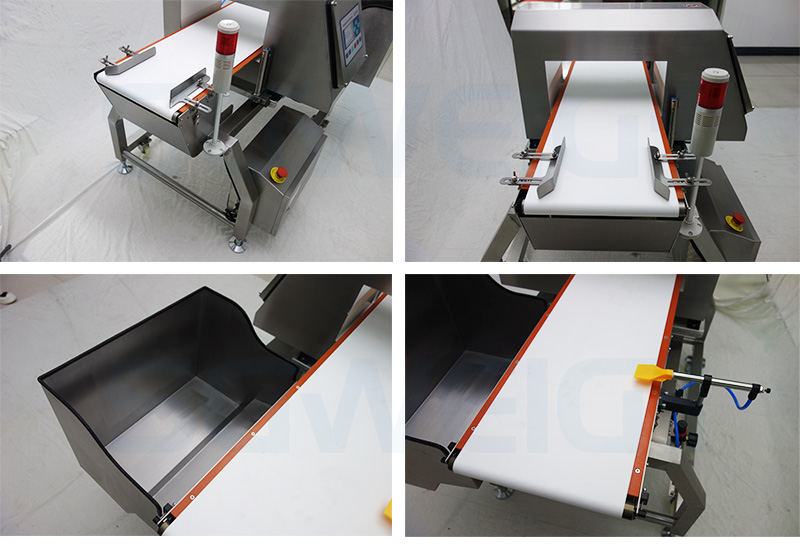

Automatic Conveyor High Sensitivity All-Metal Detector with Rejector is a critical aspect of quality control in the food industry, helping to ensure the safety and integrity of products before they reach consumers. Metal detectors are used to identify and remove metal contaminants that may be present in raw materials or introduced during processing.

Metal detectors can detect various types of metals, including ferrous (iron), non-ferrous (aluminum, copper), and stainless steel.Welcome to consult for quotation information !

Product Parameter

SG-M400

Machine Grade:Food Grade

Detect method:Electromagnetic wave detection

Detecting width:150-1000mm customized according to requirements

Detecting height:80-500mm (or custom-made)

Detecting sensitivity:Fe 0.8mm-1.2mm, Non-Fe 1.5mm- 2mm, SUS 1.5mm- 2.5mm

Detecting adjustment:Intelligent adjustable

Belt Speed:25m /min (or specified)

Alarm mode:The buzzer alarm, the motor automatically stop

Power:AC220V,50/60Hz (Or Customized)

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

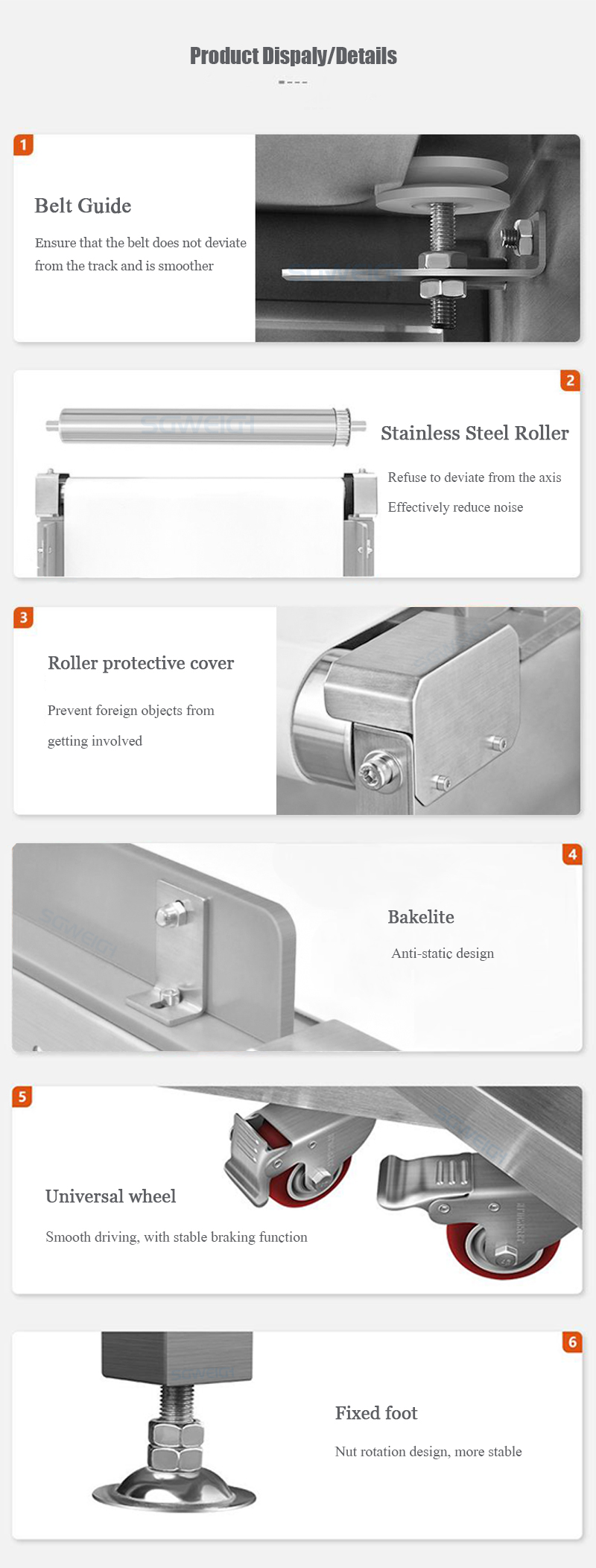

Standard Features

1.Exceptional stability and sensitivity.

2.Applicable for all metals, including ferrous, copper, stainless steel, etc.

3.Dust and waterproof stainless steel construction.

4.Can be equipped with a variety of integrated rejecter styles (push bar, flipper, air jet, etc.).

5.Safeguard processing and packaging lines.

6.For detecting magnetic and non-magnetic metals.

7.Protect your brand and preserve your reputation.

Scope of Application

This is mainly used for detecting the metal chips inside any products such as poultry, seafood, ice-cream, frozen food, sugar, tea, pharmaceutical, health care products, etc.

Company Profile

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo