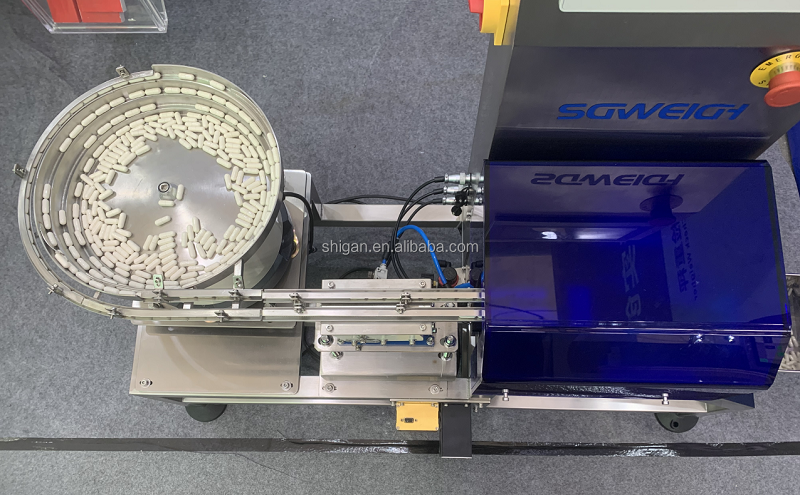

Enterprises have introduced SG-DJ10 Capsule/Tablet Sample Check Weigher in the production line to regularly inspect capsules and reduce manual operation costs. On the premise of not affecting the normal feeding of products into the finished product turnover barrel, part of the medicines are regularly extracted through the motor-driven retrieval mechanism, and then transported into the buffer bin at the checkweighing entrance through vibration, where they are automatically loaded, queued, and weighed one by one.

1. Using a vibrating plate loading specially designed for capsules and tablets, the capsules enter quickly and evenly.

2. There is no need to change the mold, and it can be used to check the weight of various types of hard capsules one by one.

3. All capsule lanes are open structures and the capsules move smoothly.

4. It is easy to clean and can avoid cross-contamination between different drugs when multiple capsules use the same capsule scale. It is suitable for multiple

capsules to use the same capsule sampling scale to check and control the loading difference.

5. The open structure can prevent the defective capsule shape from causing the rhythm of the capsule moving mechanism to be misaligned, the channel to be blocked, and

even wrong weighing to cause unqualified capsules to be mixed with qualified products.

6. The capsule will not be damaged or seriously worn during the vibrating feeding, weighing, and rejecting (optional) processes.

7. All lanes are made of 316L

stainless steel, without any other materials that may contaminate the capsule.

Hot Labels

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Checkweigher and Metal Detector Combo

Convenient Checkweigher

Weigh Labeling Machine