Product Summarize

2-300g Rotary Small Round Bottle High Quality Check Weigher are devices designed to weigh items as they move along a conveyor belt, and they are commonly used in industries such as food and beverage, pharmaceuticals, and manufacturing. Rotary Bottle Checkweigher ensure that the weight of bottles or containers falls within specified tolerances. Checkweighers are crucial in quality control processes to guarantee product consistency and compliance with regulations.Welcome to consult for quotation information!

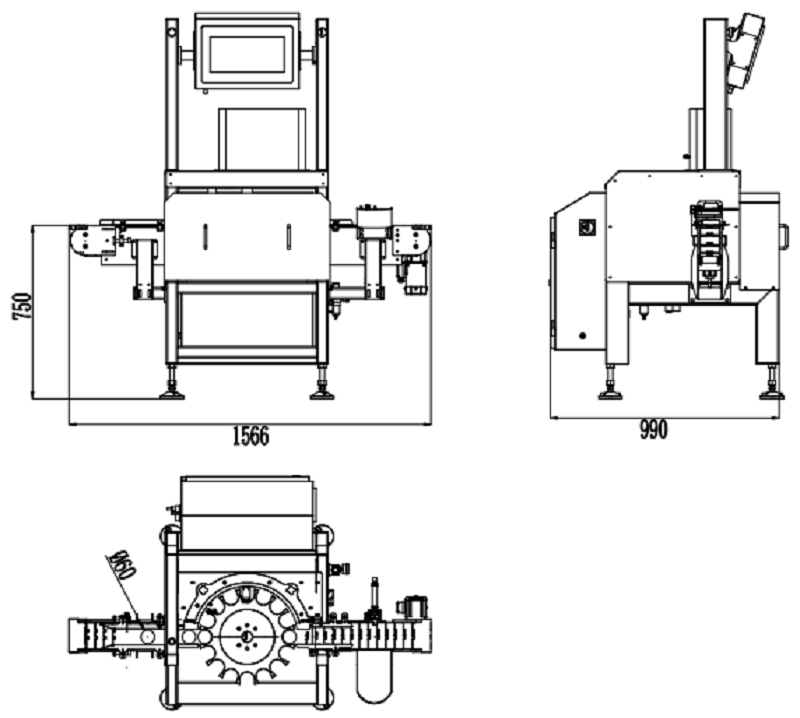

Product Parameter

Type:SG-Z

Weighing scope: 2-300g

Restrictions of product:Ф10-100 Н:20-200(mm)

Accuracy:±0.01g (Depends on products)

Division scale:0.01g

Belt Speed:0-50m/min

Highest speed:60pcs/min,120pcs/min,180pcs/min(Optional)

Chain plate width:100mm

Weight of machine:about 260Kg

Powder supply :AC220V 50HZ

Power:about 400W

Main material:SUS304

Product Characteristics

Working Principle:

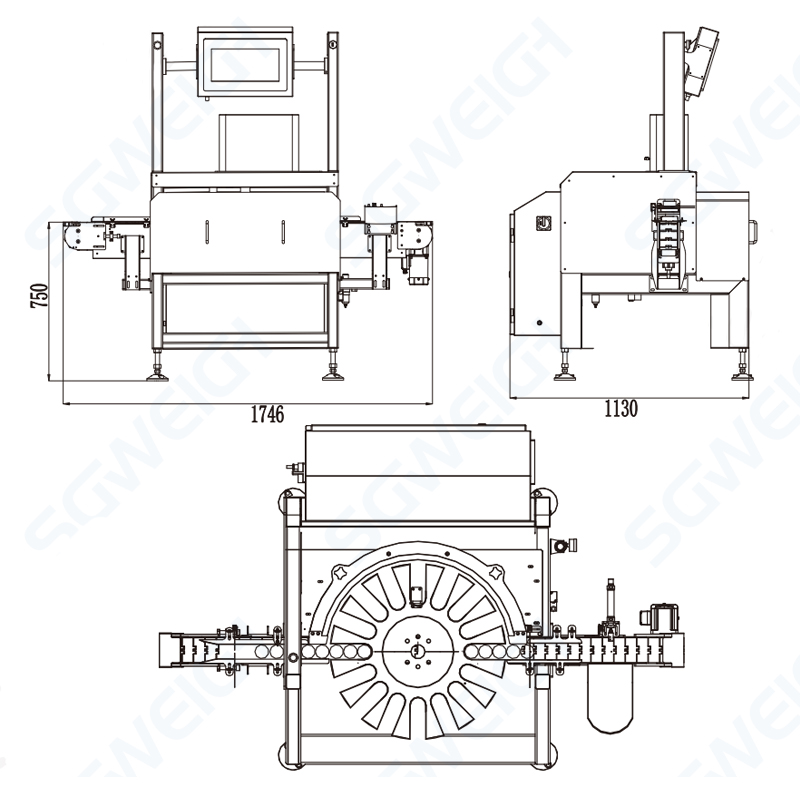

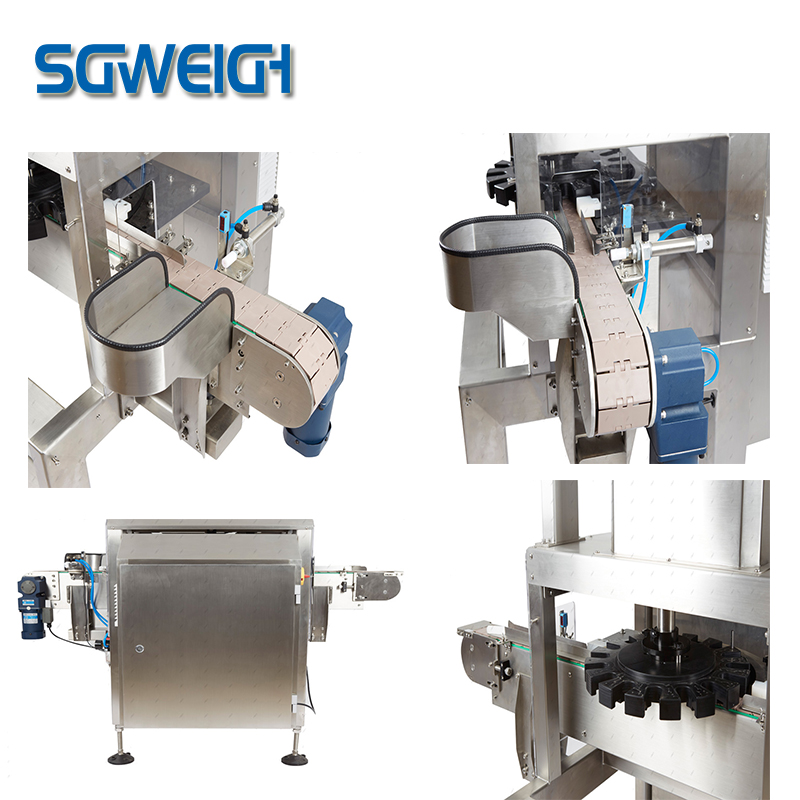

The Rotary Checkweigher is mainly composed of front-end chain plate feeding,clamping turntable,weighing module,discharging chain plate and rejection.

Front-end chain plate feeding:

The front-end feeding chain plate transports the tested products to the turntable one by one through photoelectric induction.

Clamping turntable:

The corresponding quantity of products is mainly clamped to the weighing module through the clamping turntable to ensure the accuracy of the quantity.

Weighing module:

Completes the collection of weight signals. When the product under test passes through the weighing module, all the weight data of the entire process will be analyzed and calculated to calculate the weight of the product under test. At the same time, the weighing module will determine whether the weight data obtained is within within the required weight range.

Rejection device:

When the products pass through this section of the conveyor belt, qualified products will continue to be transported backward. If they are not within the required weight range, the machine will start the rejection mechanism to remove products with unqualified weight (overweight/underweight).

Specific Application

Company Profile

Customer Visit

Exhibition

Packaging&Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Hot Labels

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Vertical Metal Detector

Checkweigher and Metal Detector Combo

Convenient CheckweigherS